Curriculum

FOOD SAFETY KNOWLEDGE

Module 1

0/1Starting Course

0/3Module 2

0/1After Intro

0/3Module 3

0/1Module 4

0/0INTRODUCTION TO PERSONAL HYGIENE AND WATER QUALITY

INTRODUCTION TO PERSONAL HYGIENE AND WATER QUALITY

· Introduction

·

· A high standard of personal hygiene is essential, especially where open food is prepared or processed.

Many potential physical contaminates such as hair or microbiological contaminates such as bacteria arise from direct contact with the person handling food during the preparation, storage, or distribution phase.

·

· System Development

· As the person responsible for food safety within the factory it is important to develop a system to ensure and monitor that the staff is fully aware of and uses:

·

o Good personal cleaning practices.

o Good personal behavior practices.

o Reporting processes for possible illnesses.

·

· Any system will have to be clearly and concisely documented and communicated in detail to appropriate staff within the company.

You must work closely with key company staff to ensure that they clearly understand the importance of such systems and how they can influence and achieve compliance.

Since the responsibility for food safety rests with you, direct verification of systems is extremely important for Basic Level requirements.

You should personally and frequently monitor activities on a regular basis and record your findings.

· Hand-Washing

·

· It is widely recognized that hands are a potential source of microbiological and chemical contamination.

Food handlers, if poorly trained and managed, pose possibly the greatest risk of microbiological contamination; in short, they may unwittingly poison foods and thus consumers.

Frequent hand-washing and good personal hygiene practices will significantly minimize the risk of product contamination.

·

· Hand-Washing

·

· You must establish and maintain a system that ensures food-handlers wash their hands:

·

o Upon entering a food handling or processing area.

o Immediately after using the toilet.

o After using a handkerchief.

o After eating, drinking, or smoking.

o After handling equipment cleaning machines or equipment cleaning utensils.

o After handling raw food or any contaminated material which could result in contamination of other food items.

·

o

o Hand-Washing Equipment

o

o More information about key hand washing equipment is given in the tabs below.

o

§ Washbasins

§ Cleaning Materials

§ Hand Drying

§ Food Preparation

§ The company must provide an adequate number of washbasins at suitable locations designated for hand-washing.

Washbasins need to have a supply of hot and cold running water (or suitably temperature controlled) of appropriate microbiological and chemical quality.

· Hand-Washing Method

·

· Food handlers should use the following method to ensure hands are appropriately clean:

·

1. Wet hands with warm running water and apply liquid soap or use a clean soap bar.

2. Rub hands vigorously for at least 20 seconds, giving special attention to the backs of the hands, wrists, between the fingers, and under the fingernails.

3. Rinse hands well while leaving the water running.

4. Dry hands with a clean single-use disposable towel or air drier.

5. Where a disposable towel is used, dispose of it without risk of contamination to the food products.

6. When turning off the water (if it is not automatically done), use dry hands or a clean disposable towel.

· Hand-Washing Verification

·

· Since hand-washing is critically important for the microbiological safety of food, the person responsible for food safety within the factory should monitor this activity carefully.

·

· You must watch your employees’ hand-washing activities on a fairly regular but non-predetermined basis to assess their compliance with the defined requirements.

You may also have to do occasional visual checks on the cleanliness of hands. Checks should be carried out and focused on risk periods (after toilet visits) and shift changes.

· Personal Cleanliness

·

· Every food handler must practice good personal cleanliness in order to minimize the risk of product contamination, be it physical, chemical, or microbiological.

In addition to hand-washing practices, there are a number of other matters that are important to ensure consumer safety:

·

o You should wear protective clothing.

o You should be aware of any ways in which injuries might occur.

o You should not wear jewelry, and you should be aware of where you have placed personal belongings.

· Protective Clothing

· Every food handler should wear protective clothing designed to protect the product from contamination. Even then, protective clothing, if not carefully assessed beforehand, can itself be a source of product contamination.

The company also needs to ensure that a sufficient quantity of protective clothing is available at all times

·

·

·

o Clean Clothing

o Hair

o Footwear

o Buttons fibers, or dirt may fall into or contaminate the product.

Therefore, food handlers must wear clean, undamaged protective clothing. Domestic clothing must not be worn.

· Injury Exposure

· If a food handler is injured, that injury could lead to the food being poisoned. You must make sure that all injuries to food handlers are covered.

If there is any risk of contamination, even with company-issued dressing or barrier protection such as a glove, the individual must be relieved of duties and not allowed to resume activities until considered fit to do so by the manager responsible for food safety.

·

·

· For injuries that are covered, the dressing must be issued by the company; and a record must be made of the issuing of this dressing.

Supervisors need to be aware of the issuing of the dressing and be vigilant in ensuring that it is in place and that it poses no risk of product contamination.

· Jewelry and Personal Belongings

·

· Jewelry, if worn, can harbor dirt and bacteria and can itself contaminate food as a foreign body. It is understood that certain jewelry may be worn but it must not pose a risk of contamination to the product.

Rings and earrings may be allowed but these must be of a design to ensure easy cleaning and they or any components cannot fall off. Good examples of acceptable jewelry are solid band rings and one piece sleeper earrings.

Watches should not be worn in the production area. Other personal effects, such as money and mobile telephones, must be stored away from any production area and never allowed in the immediate vicinity of food production.

· Importance of Hand-Washing

·

· This module has stressed, for obvious reasons, the need for rigorous hand-washing regimes.

Continually reminding your staff and verifying that they are abiding by hand-washing rules will serve to remind them of the absolute necessity for personal cleanliness at all times.

The hand-washing regime, which should instill personal discipline, must be encouraged by those responsible for food safety.

·

· Illness

· Food handlers who have an illness pose a direct hazard to the product by increasing the risk of contamination of the foods being prepared or produced.

The person responsible for food safety must be aware of the increased risk and be able to identify the symptoms of illnesses.

A procedure needs to be in place to minimize the risk of contamination and safeguard the health of the customer.

·

· Any person working with the company who exhibits any of the following symptoms must be excluded from the factory or production area until the illness has subsided and that employee has been given clearance to return to work by the person responsible for food safety:

·

o Jaundice.

o Diarrhea.

o Vomiting.

o Fever/sore throat with fever.

·

o Visible infected skin lesions (boils,cuts,etc).

o Discharges from the ear, eye or nose.

o Excessive coughing or sneezing.

· Read the tabs below for information on identifying, reporting and controlling an illness in relation to food safety.

·

o Identifying Illness

As the person responsible for food safety, you must be fully aware of the symptoms of possible illnesses and also train supervisory staff to identify signs of illness in the employees they supervise.

They should be trained to look for the visual signs of illness such as excessive sweating and high temperature.

They should also be aware of other signs such as frequent visits to the toilet.

· Reporting an illness

o In many countries it is a legal obligation for an individual to inform his or her employer if he or she feels unwell or is suffering from an illness.

You should instill a culture of openness about reporting illnesses. When employees begin working for the company, they should be trained to report illnesses and not work in the factory if they believe they are unwell.

Staff should also be encouraged to report if members of their family are unwell and may thus have infected the worker who could then infect the food, even if he or she does not seem infected. In such cases, a supervisor should make a decision on the most appropriate course of action.

· Control of an illness

o You should consult with a doctor or health practitioner to ensure appropriate tests and examinations are performed to determine that the ill employees do not return to work until it is safe.

When new employees are being considered, they should be questioned about their medical history and diseases or illnesses they have had or do currently have that could compromise the safety of the product.

In the event that the product manufactured is high risk, then medical screening of applicants before employment may be necessary as a routine matter.

· Personal Behavior

·

· A person’s behavior and personal habits can have a significant effect on the safety of a food product. Staff should be trained and supervised to ensure certain behaviors are discouraged.

Wherever possible, you should promote a culture of personal professionalism and pride in working in a food production environment. Employees should reflect the behavior expected of them.

They should be carefully supervised to ensure appropriate behavior.

· Improper Activities

· To prevent contamination of the product, people working within a production area must refrain from the following activities:

·

o Smoking.

o Spitting, chewing or eating.

o Licking fingers.

o Biting of fingernails.

o Sneezing or coughing over unprotected food, food packaging, or utensils that are used for food contact or cleaning.

·

· Preferably drinking of any liquid should not be allowed in the production area.

However, when drinking is allowed in the production area, it should be controlled and supervised to make sure safety of the product is not compromised.

Any drink vessel should be disposed of in an appropriate manner.

· Visitors

· Read below information regarding procedures for visitors.

·

o Visitor Procedures

Visitors to a factory are subject to the same personal hygiene requirements as permanent employees.

Visitors, such as contractors coming to work on equipment or perform supply services such as pest control, may not be used to working within a food production environment.

This means that there will be an increased risk of possible product contamination since there may not be proper hand-washing, wearing of appropriate protective clothing, or the proper “stashing away” of personal effects.

· Personal Hygiene for Visitors

o All visitors and contractors visiting the factory production area are subject to the same personal hygiene requirements as food handlers.

They must be provided with company-issued protective clothing and instructed to follow the equivalent standards of personal behavior as the food handlers. They are also to exhibit the equivalent standards of personal cleanliness as the food handlers.

Visitors to the factory can be permitted into the factory production area with appropriate protective clothing and instruction on hygiene standards; however, they must not be allowed direct contact with food products or pose any risk of product contamination.

Visitors to the factory such as transport drivers are usually excluded from entering the production area.

· Visitor Registration

o Regardless of the good practices employed by a company, its reputation may be compromised by malpractice and the ignorance of visitors.

You must be fully aware of all visitors to the factory, their purpose for visiting the factory, and their movements within the factory.

The method of recording such information is a visitor’s register that will not only provide this information but will also instruct the visitor what your company requirements are and how they are to be met.

They must confirm that they have fully understood the instructions and will comply with their obligations.

Visitors should always be greeted by an appropriate staff member who understands the importance of completing the register and can instruct the visitors on their obligations to meet the company’s hygiene practices.

· System Development

·

· A good water quality management system will reduce the risk of causing water-borne illnesses to customers. As the person responsible for food safety within the factory, you must develop systems that:

·

o Ensure that the staff is aware that they must use safe water during the food production process.

o Monitor the staff’s use of safe water during the food production process.

o Ensure that the staff is aware of their responsibility to identify maintenance issues for water systems.

o Monitor the staff in identifying maintenance issues for water systems.

o Ensure that the staff is aware of hazard prevention practices.

o Monitor and review the risk analysis used in identifying all possible hazards concerned with water used within the factory.

· The Importance of Water Quality

·

·

· The contamination of water can cause serious illnesses to consumers.

Water contamination is a major source of gastrointestinal illnesses, which can be fatal to vulnerable people.

· Pathogenic microorganisms in contaminated water can potentially contaminate foods when used in ingredients, ice, or steam and when there is contact with food.

Chemicals in water can also be a public health concern. It is common in some parts of the world where ground water used in food production may contain arsenic and other compounds which, when consumed by humans, can be very dangerous.

· Legal Requirements and Regulations

· Countries or regions typically have legislative requirements for water quality. As the food safety manager, you should refer to the local regulations on using non-potable water in food product processes since they differ from place to place.

The World Health Organization (WHO) has established guidelines for drinking water quality in the Codex Alimentarius. These may be adopted as a national standard, but such may not always be the case.

These requirements and regulations are in place to reduce the risk of water contamination and should protect public health if all businesses follow them correctly.

· The Codex provides the following requirements for the use of water in your facility:

·

o Facilities.

o Water in contact with food.

o Water as an ingredient.

o Water used to make ice and steam.

- Codex Requirements

- Read about codex requirements below.

- Facilities

- Water in Contact with Food

- Water Use as an Ingredient

- Water Used to Make Ice and Steam

- The Codex requirements state that an adequate supply of potable water with appropriate facilities for its storage, distribution, and temperature control, should be available whenever necessary to ensure the safety and suitability of food.

To find correct guidance for drinking water, you should study the World Health Organization’s Guidelines for Drinking Water Quality.

Non-potable water is regularly used in facilities for fire control, steam production, refrigeration, and other similar purposes where the quality of the water does not matter. Non-potable water must be identified in your facility and must have a separate system from potable systems.

· Correct Construction of Wells and Plumbing Systems

·

· Your facility must have adequate and safe wells and plumbing systems to prevent the risk of contamination by water.

As a food safety manager, you should know the requirements for the factory for water usage and also all the systems used.

With this knowledge, you can identify any maintenance problems and can thus prevent any subsequent contamination.

· Facility Requirements

· The source of potable water to your facility must be a recognized one, from either a municipal supply or private well.

For it to be acceptable for use, the water supply system must be properly constructed, properly maintained, and routinely tested to ensure the safety of the water coming into your factory.

·

·

· You must have potable hot and cold water available in processing areas. There should also be sufficient volume and water pressure to allow appropriate cleaning.

If your factory receives water from a well, the well should be tested at least once a year; however, you should carry out a risk assessment to see how often testing needs to be done.

This risk assessment may look at areas such as possible leaking of contaminates from farmland or industrial areas.

· On-Site Water Treatment

·

· If your factory has a non-potable water supply which is required to be used as an ingredient or otherwise come into direct contact with food, then this must be effectively purified to potable water quality to remove any risk of contamination.

Water can be purified on-site by a number of methods:

·

o Sand filtration.

o Membrane filtration.

o Charcoal filtration.

o Reverse osmosis.

o Ion exchange.

· Read about cross-connection and backflow below.

·

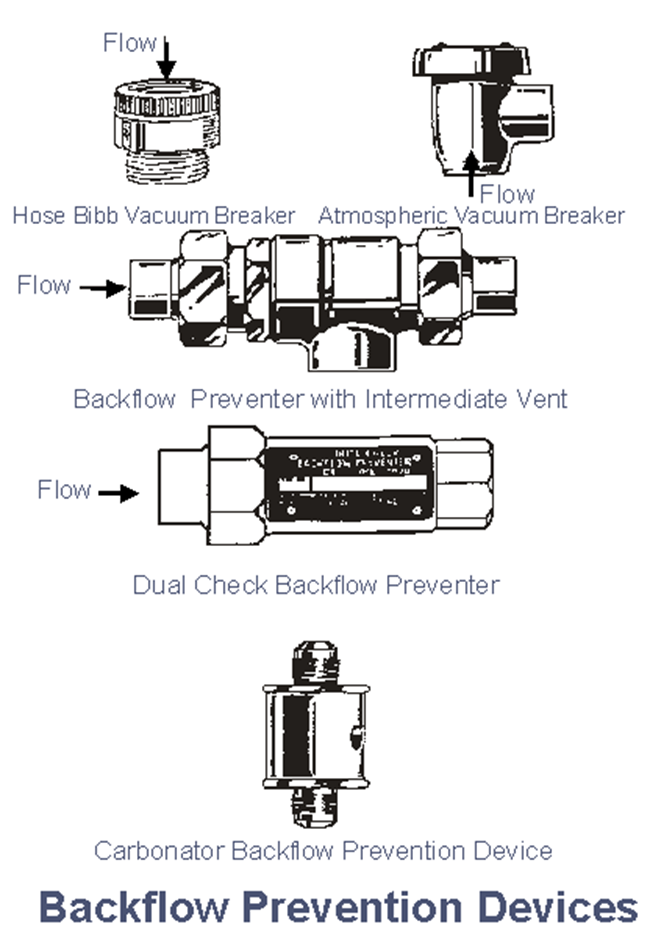

o Cross-Connection

Any connection or structural arrangement between a potable water system and a non-potable system, liquid or otherwise, through which backflow can occur.

· BackFlow

o The flow of water or other liquids, mixtures, or substances into a potable water system from any source other than the intended source.

Backflow, by its very nature of potentially mixing potable and non-potable water systems, can pose a high risk to the health of consumers.

(Source: U.S. Food and Drug Administration)

·

· Plumbing Connections to Sewer Lines

·

· Within any water conveyance system, there are two types of plumbing connections: direct and indirect.

·

o Direct Connection

o Indirect Connection

o A direct connection is a physical connection between a potable and non-potable system.

· Other than a solid physical joining to a waste or soil line. It can be either an air gap or an air break

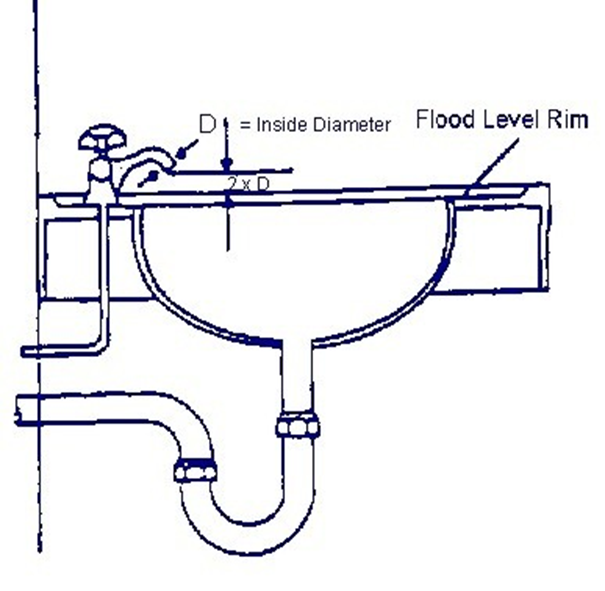

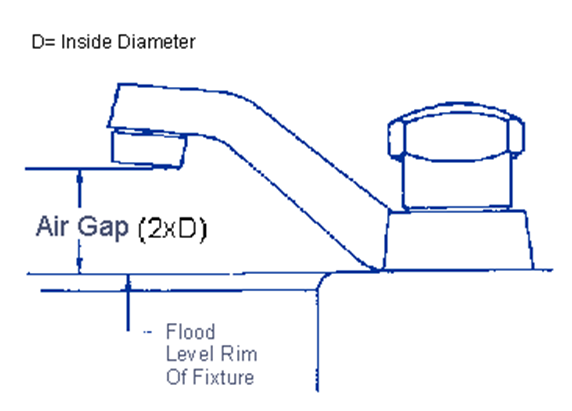

· Air Gap: The unobstructed vertical distance through the free atmosphere between the lowest opening from any pipe or outlet supplying fixture, or other device, and the flood level rim of the receptacle.

The vertical physical separation must be at least two times the inside diameter of the water inlet pipe above the flood rim level, but cannot be less than one inch.

(Source: U.S. Food and Drug Administration)

·

Figure 1: Air Gap on Lavatory

·

Figure 2: Air Gap and Effective Opening

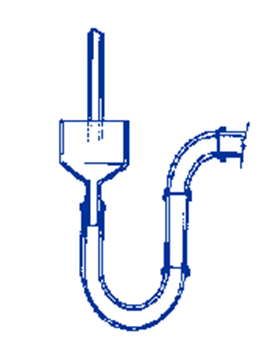

· Air Break: A piping arrangement in which a drain from a fixture, appliance, or device discharges indirectly into another fixture, receptacle or interception at a point below the flood level rim.

The connection does not provide an unobstructed vertical distance through the free atmosphere and is not solidly connected, but precludes the possibility of backflow to a potable water source into a sink or dishwasher/or fixture being drained.

(Source: U.S. Food and Drug Administration)

Figure 1: Air Break

· Monitoring

·

· The management of water quality in your company is extremely important. You must develop a routine monitoring system to ensure water safety for the various uses in food production.

You must also be aware of any risks posed by the design of the water conveyance system; for example, the cross-connections in the plumbing system.

When your company commissions any new equipment that uses water, it must be monitored prior to full use to ensure that the safety of water is not compromised.

· The main points from this module are as follows:

· A high standard of personal hygiene is of extreme importance where open food is prepared or processed.

Hand-washing is extremely important, and should be carried out correctly and diligently by everyone on the premises.

Protective clothing including hairnets and disposable gloves should be worn, to avoid contaminating food.

If a worker is ill they should not report to work. Supervisors should notice when someone is ill, and ensure that they are not working until they are deemed better.

Visitors to a factory handling food should carry out all the same safety precautions as employees.

Water quality is of high importance due to the fact that contaminated water can cause extreme illness, and may even be fatal to vulnerable people.

The WHO has established drinking water guidelines that should be followed as an outline for water safety., known as the Codex Alimentarius.

· The Codex provides requirements in the following for the use of water in your facility:

·

o Facilities.

o Water in contact with food.

o Water as an ingredient.

o Water used to make ice and steam.

· There must be adequate facilities for separately storing potable and non-potable water.

Only potable water should be used when in contact with the food product.

Potable water should be used for ice production.

Cross connections should be safe, and prevent backflow for avoiding cross contamination of potable and non-potable water.