Curriculum

FOOD SAFETY KNOWLEDGE

Module 1

0/1Starting Course

0/3Module 2

0/1After Intro

0/3Module 3

0/1Module 4

0/0CONTROL OF FOOD HAZARDS AND INCIDENT MANAGEMENT

CONTROL OF FOOD HAZARDS AND INCIDENT MANAGEMENT

·

· System Development

·

· You need comprehensive knowledge to control food hazards within your company. Lack of hazard control can cause contamination resulting in risks to consumer health or loss of product, leading to significant financial loss. Food hazards can be biological, chemical, or physical in nature.

As the person responsible for food safety within the factory, you must develop systems to ensure good practices and to monitor the staff. Staff should be fully aware of the systems and use:

·

o Good biological hazard prevention practices.

o Good chemical hazard prevention practices.

o Good physical hazard prevention practices.

o Risk analysis processes to identify all possible hazards.

· Food Safety

·

· When considering food safety, you must understand the difference between quality and safety.

Food Safety (Codex Standards): Assurance that food will not cause harm when prepared and/or eaten according to its intended use.

Food safety refers to attributes that cannot be directly observed, but instead require laboratory procedures for their measurement. These procedures include microbiological techniques or chemical analysis.

Food quality refers to attributes that can be readily observed by sight, smell, or simple measurement (such as color or condition). Food quality is easier to assess than food safety.

· Food Safety Hazards

·

· Food Safety Hazard (Codex Standards): A biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse health effect.

Food safety hazards include bacteria, viruses, parasites, hazardous chemicals, and foreign materials that can cause an adverse health effect to a consumer. In food safety management systems, hazards refer to conditions or contaminants in foods that can cause illness or injury. It is important to understand that hazards do not refer to undesirable conditions or contaminants such as:

·

o Presence of insects.

o Spoilage.

o Hair or dirt.

o Violations of regulatory food standards not directly related to safety.

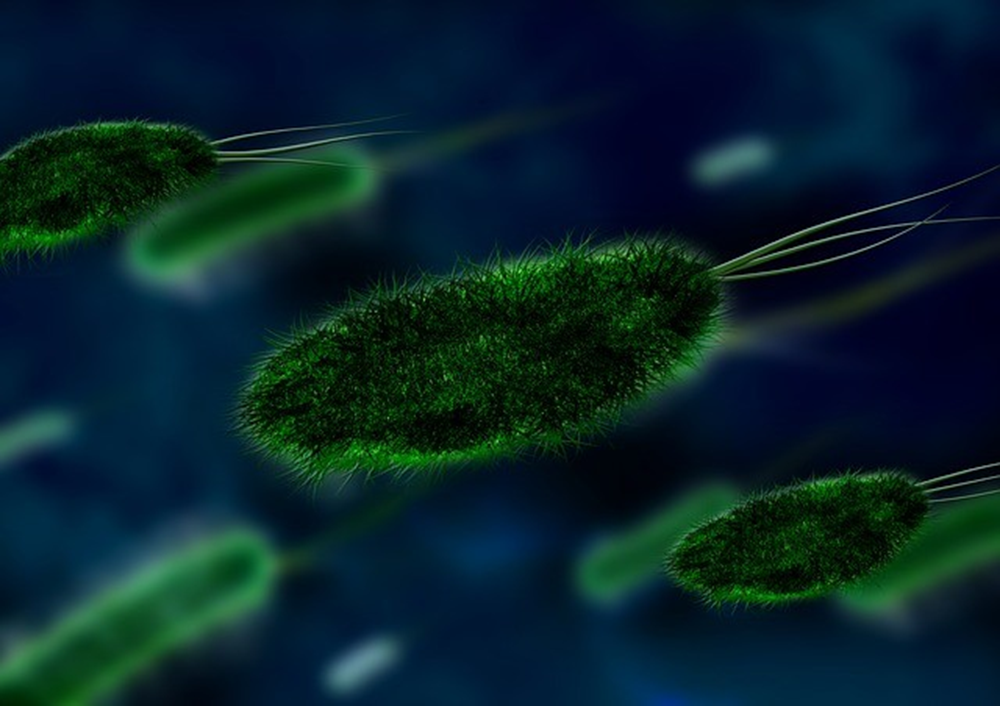

· Biological Hazards

·

· There are a number of different types of biological hazards that can be present within food. These are typically microorganisms and include:

·

o Bacteria.

o Viruses.

o Parasites.

- Practical Food Microbiology

- Microorganisms are small, living unicellular or multicellular organisms. They include bacteria, viruses, yeasts, molds, and parasites. These are not all necessarily bad for humans; in fact, many can be beneficial to humans.

There are different types of microorganisms:

- Helpful Microorganisms

Helpful microorganisms can be added to foods or are found naturally in them. In many cases, microorganisms are used in foods to help with preservation but can also be added to create unique flavors and textures.

Foods such as sauerkraut and pickles utilize fermentation as a preservation process and use microorganisms to carry out this fermentation process.

Other foods such as bread use fermentation as an essential part of their production.

· Spoilage Micro organisms

o Spoilage microorganisms affect the quality of the product, not necessarily the safety of the food. It is usually very easy to identify when a food product is affected by spoilage, by look or taste. There can be discoloration on fruit, molds on bread, or milk that tastes sour.

In some cases spoilage microorganisms can affect the safety of products. An example is that some fruits can decay by a mold called penicillium expansum. This mold produces a toxin that can affect humans.

Any foods that are found to be spoilt should be disposed of immediately, and products in the same lot should be inspected.

· Pathogenic Micro organisms

o Examples of these microorganisms that should be effectively controlled are bacteria such as Salmonella or E. coli O157:H7. The common symptoms of these are nausea, vomiting and diarrhea, and, in serious cases, death.

The presence of pathogens within humans is the main reason why washing your hands after using the toilet is essential when working with food.

· Pathogens

· Pathogens are microorganisms that cause food-borne illness. Pathogens come in three forms:

·

o Bacteria – Single-celled organisms that live independently.

o Viruses – Small particles that live and replicate in a host.

o Parasites – Intestinal worms or protozoa that live in a host animal or human.

·

· Pathogens can be found in soils; these include:

·

o Salmonella species.

o E. coli O157:H7.

o Shigella species.

o Campylobacter jejuni.

o Viruses and parasites.

· Bacteria

· Bacteria are very resilient microorganisms that are found everywhere. Some examples of where they can live and multiply are:

·

o In air, soil, and water.

o In intestines of animals and humans.

o On skins of fruit and vegetables.

o On raw meat, poultry, and seafood.

o On shells of nuts.

o On insects and rodents.

o On hands, skin, hair, and clothing of people.

·

· Because of the nature and diversity of bacteria, they can be found almost anywhere in your factory. It is, therefore, imperative that bacteria and other microorganisms are controlled to acceptable levels and, in some cases, completely eliminated in the food.

·

- Bacteria

- The problem with bacteria when concerned with food safety is that they are single-celled organisms that can live independently. When the conditions are correct, they can divide and multiply very quickly, as is seen in the example to the right.

To multiply, bacteria need moisture, nutrients, warmth, and time. Moisture and nutrients are found on most foods, so bacterial growth on foods is very common.

Bacteria cause the greatest number of deaths from food-borne illnesses. They are impossible to see with the naked eye. Taking these factors into account, it is clear that controlling bacteria can be difficult but is essential.

· Viruses

·

· Viruses are different from bacteria since they do not multiply in food. They are intracellular organisms which invade living cells and then use the cell’s content to replicate.

Since viruses do not multiply on food, they contaminate by human or animal interaction. Food-borne viral disease generally results from poor personal hygiene or lack of pest control.

Viruses can also survive and travel in water and ice, so it is essential that your water supply is adequate, safe, and regularly monitored.

· SHAPE \* MERGEFORMAT

- Controlling Viruses

- Personal hygiene for food handlers is extremely important in controlling viruses. All staff must be made aware of inappropriate personal hygiene practices, and monitoring should take place to ensure good personal hygiene is being followed.

Staff members who show symptoms of viral infection should be identified and kept away from food processing areas. If a food handler has a viral infection, then it is very easy to spread that virus. It is good practice to have a return to work policy in place for staff who have been absent as a result of a viral infection, allowing you thus to identify any viral symptoms that may still be present.

Viruses can be transmitted in water; potable water must, therefore, be used for ice- making or as an ingredient in food.

· Parasites

·

· Parasites can be unicellular or multicellular microorganisms. They can colonize in the gastrointestinal tract of humans and other animals.

More often than not these parasites have really complex life cycles where they may be in a human’s intestinal tract for a long period of time and shed cysts. These cysts are a protected form of themselves and can infect other people or animals when they are consumed.

The most common food-borne parasites are protozoan parasites and parasitic worms.

· Protozoan Parasites

·

· Protozoan parasites, which are unicellular organisms, are the most common food-borne (or water-borne) parasites. They are so common in some parts of the world that they are endemic.

Examples of protozoan parasites include:

·

o Giardia lamblia.

o Cryptosporidium parvum.

o Cyclospora cayetanesis.

o Toxoplasma gondii.

· Parasitic Worms

·

· Parasitic worms are small, multicellular organisms which can colonize in the gastrointestinal tract or other tissues of humans or animals.

Some common parasitic worms include:

·

o Anasakis simplex and related worms.

o Other seafood-associated parasitic worms.

o Trichinella spiralis and related Trichinella species.

o Ascaris lumbricoides and Trichuris trichiura.

· Controlling Parasites

·

·

· Since parasites can be found in feces, there is a risk of contamination when using manure for fruit and vegetable crops. Consider using compost that does not contain manure to remove the risk of this parasitic contamination.

Since parasites can live in water, you must use potable water for the washing, packing, and processing food products.

Thermal processing can destroy parasites; so if appropriate, use this treatment to remove the parasite risk.

· General Control Points for Biological Hazards

·

· Listed below are general control points for biological hazards:

Product Specification

It is important to be aware of the presence and number of microorganisms in food.

Many raw materials, therefore, have microbiological standards. It is common in the food industry to have specifications for the absence of microbiological contaminants.

· Control Mechanisms

Physical and chemical control mechanisms significantly affect the survival and multiplication of microorganisms; for example, a reduction in pH in fruit juice by the addition of ascorbic acid can prevent microorganisms from multiplying.

Time and temperature are important control points since cooking or freezing rapidly can prevent the growth of biological contaminants. Freezing usually stops the multiplication of microorganisms; however it does not kill them. Thermal processing will kill most biological hazards.

· Cleaning and Disinfection

The equipment used for producing, processing, and storing products should be sanitized on a regular basis. It is good practice to have a cleaning schedule in place.

The packing, storage, and distribution must be controlled so that no biological hazard can contaminate or survive on food products. This process will entail suitable packaging for the product and temperature control in storage and distribution.

· Conditions for Use

The directions you provide to the consumer are very important. Providing information on how to correctly store and cook the product can reduce the risks of biological hazards.

· Cross-Contamination

Cross-contamination must be managed so that materials cannot contaminate others. Control systems should be in place and your staff made aware of their responsibility to prevent contamination.

Your staff must also be aware of correct product handling and personal hygiene.

· Chemical Hazards

·

· There are different types of chemical hazards associated with food:

·

o Naturally-occurring chemicals.

o Intentionally-added chemicals.

o Unintentional or incidental chemical additives.

· Control points for chemical hazards must be identified during the process and storage of food products. Such can be done by using hazard analysis technique.

- Naturally Occurring Chemical Hazards

- There is a perception that if something is naturally grown or raised it will not have any chemical hazards present. This belief is not true; naturally occurring chemical hazards are present in many foods.

For example, there are toxins found in many varieties of mushrooms and some seafood. In many countries there is legislation relating to the presence or level of toxins, so you should be aware If you are using foods which may contain these toxins.

- It would be good practice to refer to legislation and analysis samples of the product before use. These chemical hazards are often classified as biological, but the important thing is that it be recognized as a hazard and controlled.

Examples of naturally occurring chemical hazards are:

- Scombrotoxin (histamine) – fish.

- Saxitoxin – paralytic shellfish toxin.

- Ciguatoxin – finfish.

- Mycotoxins – produced by moulds (fungi).

- Toxins produced by Clostridium botulinum, Staphylococcus aureus, Bacillus cereus.

· Intentionally Added Chemicals – Food Additives

·

· There are two types of intentionally added chemicals:

·

o Direct Food Additives

Direct additives are compounds such as preservatives; these include nitrites, sodium benzoate, and sulfiting agents. You must be aware of the regulations relating to the use of these compounds since legislation does differ from country to country.

Additives such as colors and nutritional additives (such as vitamins) are also direct. All direct additives must be included on all labels.

· Indirect Food Additives

o Indirect food additives include:

• Adhesives.

• Paper and paperboard components.

• Polymers.

• Adjuvants, protection aids, and sanitizers.

In most cases these indirect food additives are undesirable and migrate into the food from inappropriate packaging.

· Unintentionally Added Chemicals

· There are a number of unintentionally introduced chemicals added to foods by agricultural processes, including:

·

o Pesticides.

o Fungicides.

o Herbicides.

·

o Fertilizers.

o Antibiotics.

o Growth hormones.

·

·

· These substances are prohibited in certain countries. To ensure your company is complying with legislation where the food is sold, you should carefully review the appropriate legislation.

There are private standards and business-to-business requirements that can be stricter than legislative requirements, and the customer will closely scrutinize the product for the presence and level of substances that violate these standards.

· Controls of Chemical Hazards

· Having a management system in place that identifies sampling points and sampling levels is good practice to reduce the risk of chemical hazards. The table shows suggested areas of inspection.

·

|

Source |

Why a Hazard? |

|

Agricultural Chemicals (e.g. pesticides, herbicides) |

If improperly applied, some can be acutely toxic or may cause long term health effects. |

|

Cleaning Chemicals (e.g. acids, caustics) |

Can cause chemical burns if present in the food at high levels. |

|

Equipment Components (e.g. copper pipe fittings) |

Acidic foods can cause leaching of heavy metals from pipes and joints (e.g. copper and lead). |

|

Maintenance Chemicals (e.g. lubricants) |

Some chemicals that are not approved for food use may be toxic. |

|

Packaging Materials (e.g. tin) |

High nitrate levels in food can cause excessive detinning of uncoated cans resulting in excessive levels of tin in the food. |

· Physical Hazards

·

· A physical hazard is any potentially harmful extraneous matter not normally found in food.

They are different to biological or chemical hazards: they generally cause problems for relatively few consumers per incident.

The result of personal injuries is usually not life-threatening but can cause considerable personal distress to the consumer. Typical examples are broken teeth, cut mouths, and choking.

Examples of physical hazards:

·

o Metal fragments.

o Glass particles.

o Wood splinters.

·

o Rock fragments.

o Stones.

o Bone fragments (meat and poultry).

· Control points for physical hazards must be identified during the process and storage of food products. Such can be done by using a hazard analysis technique.

· Preventing Physical Hazards

·

· Preventive maintenance of equipment is extremely important to greatly reduce the risk of physical contamination. Equipment failure or breakage can allow physical hazards to enter foods.

This happens usually during the processing stage. Routine inspections and maintenance of the equipment is good practice. Screens and filters used in liquid processing can identify problems in equipment upstream.

By regularly inspecting the screens or filters, objects from equipment (broken machine parts or rubber seals, for example) can easily be seen and further contamination reduced.

· Control or Detection Equipment

· Detection equipment is very useful in identifying physical hazards in foods. There are a number of methods that can be used for different processes:

·

o Magnet – ferrous metals.

o Metal detector – ferrous and non-ferrous metals.

o X-ray equipment – all types of physical hazards.

o Screen or sifter – separation by size.

o Aspirator – segregation by weight.

o Riffle Board – removal of stones from beans

o Bone separator – mechanically-separated meat.

· Physical Hazards

·

· Listed below is information information about physical hazards:

·

o Employee Practices and Physical Hazards

The staff can pose a risk to foods by physical hazard contamination. In order to prevent/reduce this risk, your staff must be made aware of company policies in regard to hazard prevention. An example is the wearing of jewelry.

Your staff should also be encouraged to make you aware of any risk of possible physical product contamination they observe while at work.

· Sources and Controls of Physical Hazard

o As a food safety manager, you must have in place an effective management system that identifies the source and control points to reduce the risk of physical hazards. The table shows physical hazard control methods.

· Control of Food Safety Hazards

·

· To control food safety hazards effectively, it is important to understand the nature of possible hazards. Not all substances or microorganisms are hazardous until they reach a certain level, so it is important to know and understand the significance of these levels.

Possible hazards are always going to pose a risk to your company, so it is essential to know how to control these hazards. By using different methods such as destroying, removing, preventing, or reducing hazards to an acceptable level, contamination issues will be greatly reduced.

To control food hazards, you must have a system in place that maintains control points within the process. You must have knowledge of how to develop this system so that any change can be taken into account and managed correctly.

· System Development

·

· Food allergens can be a significant health risk to those consumers who have allergic reactions to specific foodstuffs. Allergens can contaminate food products during the preparation, storage, or distribution stages. If there is a risk that food products have been contaminated by a known allergen, the food must be immediately removed from the food supply chain.

As the person responsible for food safety within the factory, you must develop systems to ensure good practices and to monitor the staff. Staff should be fully aware of the systems and use:

·

o Good personal hygiene.

o Practices to prevent contamination by raw materials and packaging.

o Good practices in cleaning and housekeeping.

· The Importance of Allergens

· It is important to understand what a food allergy is and how it affects the human immune system. It is also important to understand the difference between food allergies and food intolerance. A food allergy is a reproducible adverse reaction to a particular food that involves the immune system. Nearly all allergens are proteins.

·

o Food Allergen

A form of food intolerance associated with a hypersensitive immune response mediated reaction in which antibodies are formed.

· Food Tolerance

o A reproducible reaction to a food which occurs without a hypersensitive immune response.

· The effect of food allergens differs by population, as can be seen in Europe.

An allergic reaction to the onion in the Western Europe is virtually non-existent. However in Eastern Europe there are an increasing number of cases where allergic reactions to onions occur.

On a global basis, approximately 1-2% of adults and 5-8% of children suffer from a food allergy. These figures are increasing each year.

· The Effects of Food Allergies

· In some cases, a reaction to a food allergen can result in death within a short period of time. A perfectly healthy individual can have a serious reaction that results in death within an hour of consumption.

Another important fact is that in some individuals as little as 1mg of an allergen can cause a serious reaction that can result in death. Many people die each year from food allergies; for example, 100 deaths in the United States in 2006 resulted from peanut allergies.

· Symptoms of an Allergic Reaction:

· There are different symptoms for allergic reactions to food. Some people suffer only very mild reactions while some can suffer very serious health effects, even death. Typical symptoms of an allergic reaction to food are as follows:

·

o Respiratory reaction, such as asthma.

o Gastrointestinal reaction, such as vomiting or diarrhea.

o Skin reaction, such as dermatitis.

o Anaphylactic shock – evidenced by a drop in blood pressure, severe constriction of airways, multiple organ failures, and/or death.

· Legal Requirements for Food Allergens

· Because of the severity of food allergens, legal requirements have been put into place to ensure the correct labeling of foods. Food labeling should inform the consumer of the presence of known food allergens as an ingredient in the food or any possible cross-contamination of a known food allergen which may have taken place during its preparation.

Legislation put into place within the EU, US, and Australasia requires specific ingredients to be clearly listed on certain foods to highlight the presence of allergens.

·

o EU – Directive 2003/89/EC as regards to indication of the ingredients present in foodstuffs.

o US – Public Law Section 201-210.

o Australia/New Zealand – Food Code Standard 1.2.3.

· As a food safety manager, you should be aware of the markets where the products you produce will be sold and thus ensure that your product is labeled in accordance with legislation.

You must appreciate that there are differing allergens specified within these legislative requirements and that these requirements may be amended and updated in line with the increasing diversity of allergen reaction to specific foodstuffs.

· Control of Allergens

· Because of the importance of food allergens to consumer health, a system for managing the control of allergens should be in place.

This system must have control measures for cleaning, packaging, and raw materials/ingredients as well as sessions for employee training and instruction.

As previously mentioned, very small quantities of certain food allergens can cause serious health effects or death, so good management of all these areas within the food business is essential.

·

· Staff Control Measures of Food Allergens

· The knowledge and behavior of the staff is extremely important in the control of allergens.

·

o Staff Awareness

All staff must be made aware of the importance of allergen control. The training should include product identification and recipe control. Where rework is used, staff should be aware of specific control measures to prevent cross-contamination.

Protective clothing soiled with a food allergen can pose a risk of contamination. Staff should be made aware that soiled clothing must be changed when working with specific food products.

· Personal Hygiene

o Hand-washing is important in allergen control since contamination can occur when working with different ingredients. Staff members must wash their hands between the uses of different ingredients.

Equipment

When using utensils for the production of food products, the staff must be trained in reducing contamination by cleaning the utensils when using them for different foods. The production of chocolate provides a good example.

Some factories make chocolate containing nuts and also without nuts. If they use the same utensils or equipment, they risk contaminating the product. The staff should clean all utensils and equipment to remove the risk of allergen contamination. It is good practice to use separate utensils for specific food products.

· Waste Control

o The staff should be aware of the correct procedures for waste disposal, particularly when the product contains allergens.

· Food Consumption

o Consumption of certain products by staff members can introduce allergens into the foodstuffs being produced. Good management practice dictates that eating and drinking shall be restricted to the canteen or external areas away from food products or ingredients. Good management practice also dictates a hand-washing policy: all staff must wash their hands before entering a food production area.

- Raw Materials and Ingredients Control Measures of Food Allergens

- It is crucial to know the status of the raw materials and ingredients that you receive from your suppliers. If the ingredients you obtain from your suppliers are contaminated with allergens, then all your precautions you take in your factory to control allergens will be pointless. Ask questions of your suppliers. For example, ask them about their cleaning schedules and the ways they store their products.

- If you have an allergen as an ingredient or an ingredient contains an allergen, then these products must be clearly identified and controlled within your factory. The preferred means of identification is clear labeling of the product. Staff members can, therefore, easily identify and control the use of these products throughout the process.

It is essential to keep comprehensive records of all recipe batches and production schedules to verify the effective control of allergens.

· Packaging Control Measures of Food Allergens

·

· The control of the use and storage of packaging is important to reduce possible cross-contamination by allergens. Incorrect storage of packaging can introduce allergens into the product.

Packaging that is meant to contain “allergen free” products should be securely stored away from other packaging. The most common problem in allergen control is the placing of product into incorrect packaging.

Special emphasis should be placed on process control when there is a change in a product’s recipe on the production line. Measures must be put in place to ensure that the product is placed in correct packaging. Controls at the packaging stage of the product are extremely important.

· Cleaning Control Measures of Food Allergens

·

· Allergens can contaminate products when cleaning is not done competently. Cleaning within the factory should be carried out on a comprehensive cleaning schedule with subsequent monitoring for effectiveness. Allergen-dedicated cleaning equipment should be used to clean all areas that pose a contamination risk.

As a food safety manager, you are responsible for developing an effective cleaning schedule that minimizes the risk of all possible allergen contaminants on equipment and the factory environment.

·

· Your emphasis should be placed on equipment that requires dismantling for effective cleaning to ensure all allergen contaminants are removed before reuse. Your staff should be aware that any spillages must be cleaned immediately.

· Production Measures of Food Allergens

· Production processes and schedules have a significant influence on the control of food allergens. Where possible, foodstuffs that contain allergens should be processed on specific equipment or in specific areas of the factory to reduce the risk of possible cross-contamination. But other measure should also be used to control food allergens.

·

v · For example, installing physical barriers such as doors between processing rooms reduces the risk of cross-contamination. Dedicated utensils that are used just for specific foodstuffs will help reduce allergen contamination; for example, utensils that are color-coded for use on products that contain nuts should not be used for any other foodstuff.

· For example, installing physical barriers such as doors between processing rooms reduces the risk of cross-contamination. Dedicated utensils that are used just for specific foodstuffs will help reduce allergen contamination; for example, utensils that are color-coded for use on products that contain nuts should not be used for any other foodstuff.

The movement of materials and equipment within your factory will also help reduce the risk of allergens contaminating products. Production scheduling is a key in the control of food allergens.

Scheduling sufficient time for effective cleaning, for example, will reduce the risk of allergen contamination. Reworking a product back into the production line is a high-risk process because the identity and status of the product can be lost if the control measures are not in place. The loss of identity means allergens can easily be put into a product that is not labeled to indicate the presence of an allergen.

· Corrective Actions

· Because of the severity of the food allergen, it is essential to take corrective action as soon as you are aware of any contamination or incorrectly labeled product.

The product should be quarantined in the factory and a decision made on the use or disposal of the product.

However, if the product is already in the distribution system and could be consumed by the buyers, actions to affect product recall must be initiated.

· Evaluation of Incidents

·

· In many countries there is a legal obligation to have procedures in place to ensure that if a company suspects or is aware that it has placed unsafe food on the market, the company must quickly and effectively withdraw the product from the market and inform the customers. A poorly controlled incident management system will have a direct effect on the reputation and commercial well-being of your company.

As a person responsible for food safety management, it is imperative that you have a system in place to:

·

o Identify when an incident is or has occurred.

o Assess and analyze the significance of the incident and the potential risk to the consumer.

o Decide upon the appropriate action to take to protect consumer safety and the reputation of both your company and your customers.

· Evaluation of Incidents

·

· Incident: Any event where, based on the information available, there are concerns about actual or suspected threats to the safety or quality of a product that could require intervention to protect consumers’ interests.

In any working day, information about potential problems with food products is continually entering and transferred around a company; for example, raw materials are outside agreed specification or a piece of equipment has broken down or malfunctioned.

There must be good and quick internal communication to make sure that information about product problems, and more importantly incidents, are collected and quickly assessed by you and your colleagues to understand their significance and impact.

· Identification

· You will have to analyze and make judgments about what to do when issues or incidents occur. You will have to decide what action to take, if any.

The process of identifying incidents is based on your knowledge of the likelihood of something occurring and its possible severity or effect.

It is very much linked into the understanding of hazards in the workplace and knowing your raw materials, the manufacturing process, product, suppliers, and people working with the product. The keys to quickly identifying an incident are knowledge, communication, training and vigilance.

Since you will be responsible for deciding upon and coordinating actions when a problem occurs, communication between you and your colleagues is essential to keep all informed about what is going on or has been revealed. Their cooperation is vital in maintaining control of a situation.

Handling complaints and analyzing them correctly are key factors in the relationship between you and your customers. There should be an accurate and timely transfer of information

· Analysis

· To ensure a correct judgment is made on the action to be taken to safeguard consumer safety, you must carefully screen the information you have. Accurate information and data is necessary, but on some occasions information may not always be readily available. Then your knowledge and experience as the food safety specialist within your company becomes vital.

When you become aware of an issue or incident, you must gather as much information as possible in order to understand fully the hazard, the nature of the complaint/issue, and its significance.

There are three steps to the analysis of incidents:

·

1. Identifying the hazard’s effects: The nature of the possible effects on consumer safety.

2. Assessing the risk to the consumer: As accurate an assessment as possible of the exposure to the consumer and the safety risk involved.

3. Assessing the actions required: Determining the options available to ensure consumer safety and making the decisions about what actions are appropriate and must be taken.

· Analysis

·

· Decisions should be made using knowledge and advice from a number of reliable sources such as the expertise of employees with the company, reference to literature, government officials, research associations, consultants, and/or customers.

The decision-making process, however, should be carried out in a timely manner since delay could lead to increased risk of exposure to customers, which should be avoided at all costs.

If your company supplies large retailers and manufacturers, these companies may have highly qualified staff that can also assist you in making necessary decisions.

· Required Action

· There are four courses of action which can be taken following careful decision-making:

·

1. Review, revise, and continue to monitor the current situation.

2. Quarantine the product within your control but do not inform customers.

3. Provide information to customers.

4. Initiate a product recall.

·

· You may determine after careful consideration that the information and data reviewed indicates that no significant corrective action is required at that time. But you will need to continue to monitor the situation carefully and frequently.

· Complaint Handling

· The importance of an effective complaint-handling system cannot be emphasized enough. Complaint feedback provides invaluable information to you as the person responsible for food safety on your performance and the effectiveness of food safety and quality systems. If there is an incident, an effective complaint handling system will provide you and your colleagues with vital information, allowing you to accurately assess the risk and thus take appropriate action.

Being proactive in handling complaints means that you must identify the severity and the significance of the complaints.

All companies within the supply chain should have effective procedures for handling compaints and understand how information gathered relates to product safety and their customers.

These procedures should be fully documented with specific personnel trained to handle them. There should be an individual available at any time within each organization who is responsible for dealing with serious complaints.

Consumers tend to complain directly to the brand owner or to the organization who sold the product to them. Thus there is a shared responsibility for the assessment of complaints in determining their source and importance. Since you are the person responsible for dealing with complaints, you must fully understand your customers’ needs.

· Complaint Handling Required Action

· All complaints are important. There should be a procedure in place which specifies:

·

o Who is responsible for dealing with complaints.

o How a complaint is investigated.

o How complaints are reviewed.

o How a complaint investigation is reported and, where appropriate, information about the investigation is provided to the complainant.

o How much time is required to investigate and to document (or report ) on the outcome of the investigation.

·

· The regular review of complaints is a useful practice to help you understand the performance of your food safety management system and to identify any potential hazards which you may be unaware of.

· System Development

·

· As the person responsible for food safety within the factory, you must develop procedures to effectively quarantine an unsafe product:

·

o Ensure the training of the employees in the product quarantine system.

o Monitor staff on the practices involved with the product quarantine system.

o Recall a product quickly and effectively.

o Ensure the training of the employees in the product recall system.

o Monitor employees as they take the steps to recall a product.

o Develop guidelines to discipline and/or retrain employees in product quarantine practices and product recall procedures.

· Product Quarantine

· If a product is unsafe and you have decided that the situation dictates that the product must not be dispatched to any customer, the product shall be immediately quarantined and under no circumstances released from your control. If you believe there is significant risk to the consumer or reputation of your customer and the product has already been dispatched and is not now directly controlled by your company, you must take urgent steps to inform your customers.

Customers will have differing requirements in place and will react differently. You need to provide as much accurate information to them as possible to allow them to act quickly to quarantine the product in their supply chain.

Quarantine means that the product is held under secure conditions to ensure that it is not used or dispatched. Under no circumstances can it be used until authorization for its movement or use is given by an appropriate person. A product may be quarantined for a number of reasons:

·

o You have identified that the product is unsafe.

o A product has been returned from a customer and thus should not be used.

o You have identified that the product is potentially unsafe and is being held pending further investigation or checking before a decision can be made.

· If you are the person responsible for food safety, it is important that you be fully aware of the quantity, condition, and status of all quarantined products under your control.

· Product Quarantine – Required Action

· Factories are busy places. Preferably quarantined products should be physically isolated to a clearly-designated area where access is restricted to employees authorized to enter this area.

·

· In many factories, however, this is not normally the case; so the product must be clearly marked or identified as being quarantined and employees must be trained to recognize the product status and the significance if the product is used or dispatched.

It is advisable that all quarantined products be physically marked with very recognizable colored labels, marks, or symbols which are not easily removed. (Products should be marked even if placed in designated quarantine areas).

You should be fully aware of any possibility that the quarantined product could be accidentally used or dispatched by employees or staff and introduce procedures to minimize the risk of such happening.

This process should involve key staff/employees who are handling, storing, or dispatching the product.

· Product Recall

· In the event that there is evidence that the product poses a risk to the health of consumers and there is likelihood that consumers have bought or could consume the product, you must recall the product.

Product Recall:

The process by which a product is removed from the market, where the product has reached consumers and they are advised to return or destroy products supplied to them.

· The Codex Code of Practice – Recommended International Code of Practice General Principles of Food Hygiene CAC/RCP 1-1969, Rev. 4-2003 states:

“Managers should ensure effective procedures are in place to deal with any food safety hazard and to enable the complete, rapid recall of any implicated lot of the finished food from the market.

Where a product has been withdrawn because of an immediate health hazard, other products which are produced under similar conditions, and which may present a similar hazard to public health, should be evaluated for safety and may need to be withdrawn. The need for public warnings should be considered.”

· Product Recall

·

· As the person responsible for food safety, the development and maintenance of product recall procedures rests with you.

You must gain the cooperation and commitment of your management and colleagues so that when a serious problem arises you have full support to deal authoritatively and effectively with the situation.

In operation, the product recall process is complex and will become more complex as a company grows and the number of customers increases, but the principles that should be in place to support an effective product recall are relatively simple.

· Procedures

·

· As with the development of any procedure, you must carefully define: who, what, how and when.

Procedures must be documented. They must focus on consumer safety at all times. They must be followed at all times. Key operations are:

·

o Restriction of any further unsafe products entering the supply chain.

o The accuracy of information regarding the location of unsafe products.

o The accuracy of information regarding your customers.

o The operational method for communicating with your customers and other interested parties.

o Since customer safety is paramount, you should make provision that you or a trained deputy be available at all times.

· Communication

· Good communication is vital to ensure that the safety of consumers is not compromised. There are three important principles for effective communication in incident management:

·

1. There must be well-defined communication pathways.

2. Communication must be accurate and easily understood.

3. Communication processes must be fast and effective.

· In a product recall, speed and accuracy of communication are vitally important. Customers should be contacted without delay.

Communication is a two-way process, so you need to confirm your company’s contact data to your customers and suppliers. You should have access to your emergency contact list at all times, allowing communication at any time.

All contact data (your company, customers, and suppliers) must be accurate, and there must be a defined procedure in place to maintain the currency of this data.

· The main points from this module are as follows:

· Food Safety Hazard: A biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse health effect.

There are a number of different types of biological hazards that can be present within food. Pathogens are microorganisms that cause food-borne illnesses and include:

Bacteria – Single-celled organisms that live independently.

Viruses – Small particles that live and replicate in a host.

Parasites – Intestinal worms or protozoa that live in a host.

Different control mechanisms for biological hazards include:

·

o Time and temperature.

o Correct sanitization of equipment.

o Correct product handling and personal hygiene.

·

There are different types of chemical hazards associated with food:

·

o Naturally-occurring chemicals.

o Intentionally-added chemicals.

o Unintentional chemical additives.

· Having a management system in place that identifies sampling points and sampling levels is good practice to reduce the risk of chemical hazards.

A physical hazard is any potentially harmful extraneous matter not normally found in food, such as:

·

o Wood splinters.

o Stones.

o Metal fragments.

· Regular inspection of equipment can reduce chances of contamination.

- Food Allergen: A form of food intolerance associated with a hypersensitive immune response mediated reaction in which antibodies are formed. In serious cases allergic reactions can result in death.

Legal requirements state that food labeling must inform the consumer of the presence of known allergens as an ingredient, or the possibility of cross-contamination of a known food allergen.

Procedures involving staff who work with allergens and equipment used near allergens need to be set in place and followed.

· Incident: Any event where, based on the information available, there are concerns about actual or suspected threats to the safety or quality of a product that could require intervention to protect consumers’ interests.

In many countries companies are legally obligated to withdraw a product from the market and inform the customers if they suspect or are aware that they have placed an unsafe food on the market.

Product quarantine and product recall are two actions for if this has occurred.

Product quarantine: Product is held under secure conditions to ensure that it is not used or dispatched.

Product recall: Product is removed from the market, if the product has reached consumers they are advised to return or destroy products supplied to them.